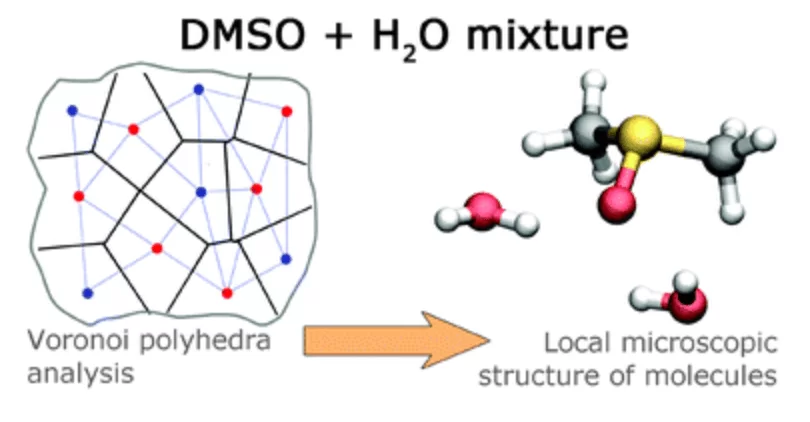

The Right Methodology For Formulating Dimethyl Sulfoxide Mixture.

Formulating the right Pharmaceutical-grade DMSO mixture is as important as any other aspect of their use in therapeutic intervention and thus requires equal attention.

It includes the choice of the right ingredients and their accurate concentration for making the accurate mixture. Adding to the prior elements, administering the proper dosage while adjusting the amount applied over a requisite period and their storage can make a difference. So, without any delay, let’s dive into the most important part:

Recommended ratios for Dimethyl Sulfoxide mixing:

Given below is a list of possible ratios for ingredients mixing and the application schedule :

50-50 mix: This part contains a mix of water with aloe vera gel or silver colloidal, and the other half contains a 99 % concentration of pharmaceutical DMSO. It is recommended that this formulation be applied regularly for 1-4.

70-30 mix: It is a concentrated version of the previous formulation, which contains the same constituents but in a different ratio. Considering the requirement of a higher concentration of dimethyl sulfoxide, 1 part of the water and aloe vera gel/silver colloidal mix is added to 2 parts of the main chemical compound. This mix is used 1-2 times a day,

10- 90 mix: It is a very mild and diluted version that is excellent for sensitive skin. In this case, 1 part of Pharmaceutical-grade DMSO is added with the choice of carrier or galenic base, making cream and ointment for day-to-day use.

Formulations procedure and tips:

Extra precautions must be considered if you want to create a blend instead of buying a tried and tested formulation. Ensure that your Pharmaceutical-grade DMSO mixture has a carrier such as - aloe vera juice, distilled water or silver colloid.

It is preferable to use aloe vera juice rather than a gel as they contain thickeners or emulsifiers to create a certain consistency.Put extra effort into recovering it from a trusted source or brand that is not adulterated or holds chances of toxicity due to preservatives or other chemicals to make it stable.

Due to their inert nature, the ingredients are usually mixed in a glass bottle, eliminating the possible contamination risk.The mixing results in an exothermic reaction where the original ties of the ingredients are broken, aiding Dimethyl Sulfoxide and the carrier to form new bonds, releasing heat.After this, we have the final product in hand, which is stored in the same glass container with a dropper and measuring sign to help the application process at the desired area.

Suggestions for dermal application:

For application in larger areas generally, a 50-50 mix works the best. It takes a maximum of 20 minutes to dry out.Sometimes, it leads to skin redness or itching, which is normal and fades away with time, but if it persists, try diluting it to a ratio of 1 part Pharmaceutical DMSO to 3 part carrier.As it is already well-known as a drying agent, reducing the percentage helps in the more frequent application without drying out the skin.If your skin feels dry, use a hydrator such as coconut oil to improve the condition or rest your skin before resuming the application process.

Mixture handling and storage of Dimethyl Sulfoxide

When dealing with a market-purchased composition, always make it a point to read the label and verify if it’s packed in a glass container.Those stored in plastic can carry requisite chemicals into the bloodstream, so be extra cautious.These safety practices can help you formulate the most effective Pharmaceutical-grade DMSO mixture at home, serving as a low-cost alternative to help you heal.

Why Probiotics May Be The Answer To Your Problems

Why Probiotics May Be The Answer To Your Problems

Are Your Levels of Heavy Metals Dangerously High?

Are Your Levels of Heavy Metals Dangerously High?